Logistics optimization is the strategic process of streamlining supply chain operations to minimize costs while maximizing efficiency and customer satisfaction. In today's competitive business environment, companies that master logistics optimization gain significant competitive advantages through faster delivery times, lower operational costs, and improved customer service.

The Importance of Logistics Optimization

Logistics represents one of the largest cost components in most businesses, often accounting for 5-15% of total revenues. Optimizing logistics operations directly impacts profitability and customer satisfaction. Key benefits include:

- Reduced transportation and warehousing costs

- Faster order fulfillment and delivery times

- Improved inventory turnover and reduced waste

- Enhanced customer satisfaction and retention

- Better resource utilization and operational efficiency

- Increased market responsiveness and flexibility

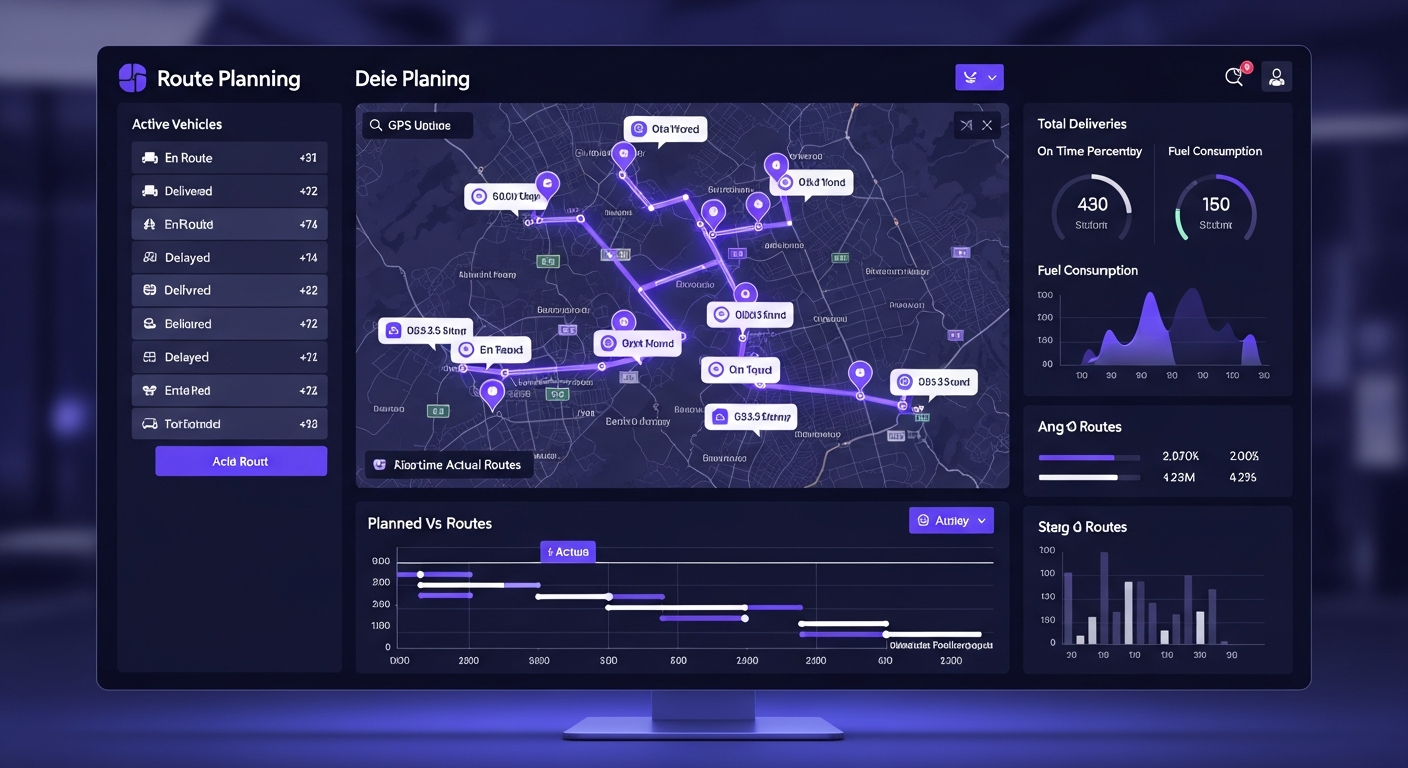

Route Optimization

Route optimization is one of the most impactful ways to reduce logistics costs. By determining the most efficient delivery routes, companies can significantly reduce fuel consumption, vehicle wear and tear, and delivery times.

Key Route Optimization Strategies

- Dynamic Route Planning: Using real-time traffic data and GPS technology to adjust routes based on current conditions

- Vehicle Consolidation: Combining shipments to achieve better fuel efficiency and reduce the number of trips

- Multi-Drop Optimization: Sequencing multiple stops in the most efficient order to minimize total distance and time

- Telematics Integration: Monitoring vehicle performance and driver behavior to optimize fuel consumption

Warehouse Location and Network Design

Strategic placement of distribution centers and warehouses is fundamental to logistics optimization. The location of these facilities directly impacts transportation costs, delivery times, and service levels.

Considerations for Network Design

- Geographic Proximity to Customers: Locating warehouses closer to customer concentrations reduces delivery distance and time

- Transportation Hub Access: Positioning facilities near major highways, ports, or airports improves connectivity

- Labor Availability: Considering local labor markets for warehouse and logistics operations

- Facility Costs: Balancing real estate and operational costs against service benefits

- Demand Forecasting: Aligning network capacity with projected market demand

Inventory Management Integration

Effective logistics optimization requires close coordination with inventory management. Carrying too much inventory increases storage costs and obsolescence risk, while carrying too little risks stockouts and lost sales.

Integration Strategies

- Just-in-Time (JIT) Delivery: Coordinating delivery schedules to match production or sales cycles

- Safety Stock Optimization: Maintaining appropriate buffer stock levels to balance costs and service levels

- Cross-Docking: Transferring goods directly from inbound to outbound shipments, minimizing storage time

- Demand-Driven Logistics: Aligning supply chain operations with actual customer demand rather than forecasts

Technology and Automation

Modern logistics optimization relies heavily on advanced technologies to improve visibility, reduce errors, and automate repetitive tasks.

Key Technologies

- Transportation Management Systems (TMS): Software platforms that manage freight logistics and optimize transportation operations

- Warehouse Management Systems (WMS): Systems that control inventory and warehouse operations

- Real-Time Tracking: GPS and RFID technology for complete supply chain visibility

- Automated Sorting and Handling: Conveyor systems, robotic arms, and automated storage to speed up warehouse operations

- Artificial Intelligence and Machine Learning: Predictive analytics for demand forecasting and optimization

- Internet of Things (IoT): Sensors monitoring temperature, humidity, and location for perishable goods

Last-Mile Delivery Optimization

Last-mile delivery—the final segment from the distribution center to the customer—often accounts for 50% of total logistics costs. Optimizing this crucial segment is essential for competitive advantage.

Last-Mile Strategies

- Delivery Window Flexibility: Offering customers flexible delivery windows to consolidate routes

- Local Delivery Partners: Using regional carriers or crowdsourced delivery for more efficient final delivery

- Customer Pickup Options: Providing parcel pickup locations to reduce home delivery requirements

- Route Density Optimization: Focusing delivery operations in high-density areas first before serving remote locations

Sustainability in Logistics

Modern logistics optimization increasingly incorporates sustainability considerations, which often align with cost reduction goals:

- Alternative fuel vehicles (electric, hybrid, natural gas)

- Modal shifts (using rail or maritime shipping instead of trucks for long distances)

- Packaging optimization to reduce weight and material usage

- Carbon footprint tracking and reporting

- Urban consolidation centers for city deliveries

"In logistics, every percentage point of improvement directly impacts the bottom line. Small optimizations compound into significant competitive advantages."

Performance Metrics and KPIs

Measuring logistics performance is essential for identifying improvement opportunities and tracking progress:

- Cost Per Shipment: Total logistics cost divided by number of shipments

- On-Time Delivery Rate: Percentage of shipments delivered within promised timeframe

- Delivery Speed: Average time from order placement to customer delivery

- Freight Costs: Cost per unit of weight or value shipped

- Warehouse Efficiency: Orders processed per labor hour

- Inventory Turnover: How quickly inventory is sold and replaced

- Damage and Loss Rates: Percentage of shipments arriving undamaged

- Carbon Emissions: Total CO2 emissions per shipment or unit

Best Practices for Logistics Optimization

- Continuous Improvement: Regularly analyze performance data and identify optimization opportunities

- Supplier Collaboration: Work closely with carriers and logistics partners to align goals

- Technology Investment: Implement modern logistics software and automation solutions

- Data-Driven Decisions: Use analytics and business intelligence to guide optimization efforts

- Scalability Planning: Design logistics networks that can grow with business needs

- Risk Management: Develop contingency plans for disruptions in transportation or warehousing

Conclusion

Logistics optimization is a strategic imperative for businesses seeking to improve profitability and customer satisfaction. By implementing comprehensive optimization strategies—from route planning and warehouse network design to technology integration and last-mile delivery innovation—companies can transform their supply chains into competitive advantages. Success requires a commitment to continuous improvement, strategic use of technology, and collaboration with logistics partners. Organizations that master these elements will enjoy reduced costs, faster delivery, and enhanced customer loyalty in an increasingly competitive marketplace.